2025-05-14

2025-05-14

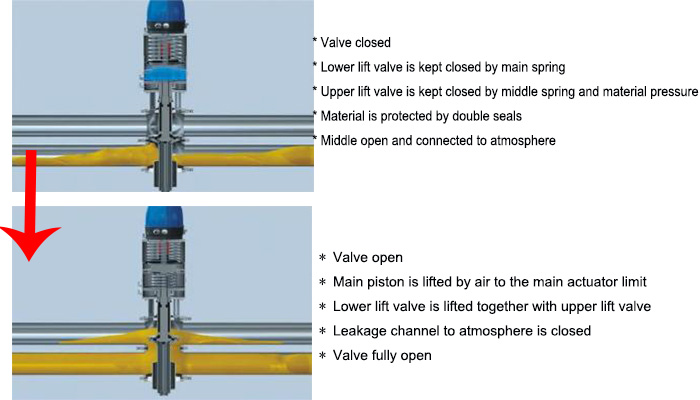

Mixproof valve is a highly hygienic double-seal valve. It is remotely operated by compressed air. The valve is in a normally closed state when the operation is not started. Through the interface between the two fluids, this system can achieve a synchronous process in the two valve bodies, preventing the possibility of material contamination. The leakage chamber and the leak detector can be self-cleaned by the valve lifting. The valve has excellent application in the food and beverage industry, especially in the beverage and dairy industries.

· Valve core pressure balance

· Valve core can be sterilized up and down

· Ultra-long life design

· Anti-water hammer effect

· Very flexible valve body combination

· Online in-situ CIP cleaning and SIP sterilization

· Self-draining

· Certification: 3-A-85-03, FDA 177.2600, CE-PED/97/23/E

The DONJOY mixproof valve is an advanced hygienic solution designed for high-precision fluid control in critical industries. Featuring a double-seal mechanism with compressed air operation, it ensures contamination prevention through synchronized dual-valve processes and self-cleaning leakage chambers. Its standout advantages include pressure-balanced valve cores, bidirectional sterilization capability, water hammer resistance, and modular flexibility. With integrated CIP/SIP functionality, self-draining design, and compliance with 3-A, FDA, and CE-PED certifications, this valve excels in beverage and dairy applications where strict hygiene, operational durability (over 100,000 cycles), and zero cross-contamination are paramount. The combination of remote automation and robust engineering makes it a benchmark for hygienic fluid management in food-grade environments.

Why sanitary stainless steel butterfly valves corrosion resistant?