2022-10-29

2022-10-29

Q: How to select suitable lobe pump?

A: Firstly, you should know the viscosity of the medium that the lobe pump will be used for and required flow rate & head/pressure.

According to the viscosity, we will suggest suitable rotation (RPM). If viscosity of the medium is too low, ≤500cps, we suggest to use centrifugal pump, not lobe pump.

According to required flow rate and rotation, we will suggest suitable bare shaft lobe pump.

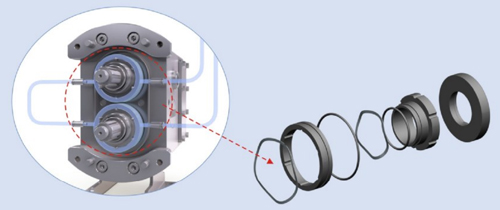

If temperature of the medium is ≥80℃, we suggest to use double mechanical seal, also called water-cooled flushing mechanical seal. For easily solidified mediums, such as chocolate, syrup, honey, it is better to use double mechanical seal TC/TC/EPDM.

DOUBLE MECHANICAL SEAL / WATER-COOLED FLUSHING MECHANICAL SEAL

For easily solidified mediums, we suggest to equipped the lobe pump with heat jacket.

LOBE PUMP WTIH HEAT JACKET

According to the viscosity and required head/pressure, we will suggest suitable motor.

Lobe pump can be equipped with various configurations, such as explosion-proof motor, servo motor, flange hopper, trolley and console, built-in safety valve, external safety valve, etc.

Why sanitary stainless steel butterfly valves corrosion resistant?