2025-06-24

2025-06-24

Lobe pump are known for their high efficiency in liquid transfer, especially when transferring viscous and shear-sensitive fluids. Their positive displacement operating principle and design enable steady, low-pulsation flow, which is critical in a variety of sanitary applications. The efficiency of a lobe pump is affected by factors such as fluid viscosity and pump design.

Lobe pump are positive displacement pumps, which means that every time they rotate, a certain amount of liquid is trapped between the rotor and the pump housing. This ensures a steady flow, regardless of changes in pressure or viscosity, which is critical for many industrial processes.

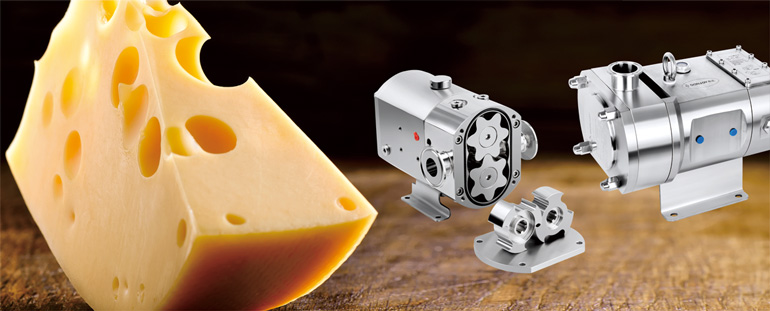

Their design ensures that pulsation and shear are minimized. Lobe pumps are designed with hygienic standards in mind, with smooth surfaces, easy cleaning (CIP/SIP), and sterilization options. This makes them suitable for a wide range of applications, including the food, beverage, cosmetics, dairy, and pharmaceutical industries.

DONJOY lobe pump working video:

1. Gentle product handling:

Lobe pumps excel at handling low-viscosity and high-viscosity fluids and can maintain a constant flow rate.

2. Low shear operation:

The non-contact impeller and smooth flow path of the rotary pump minimize the shear stress of the conveyed medium, which is particularly important when handling sensitive or delicate fluids, such as the food and pharmaceutical industries, where maintaining product integrity is critical.

3. Low pulsation flow:

The influence of rotors of different configurations on the pump is crucial, especially in terms of pulsation. For example, the butterfly rotor of the Dongzheng rotary pump can achieve smaller pulsation and reduce flow loss.

4. High volumetric efficiency:

The close tolerance between the rotor and the pump housing (non-contact, driven by an external timing gear) minimizes backflow (slip). This ensures that most of the fluid sucked into the pump can be effectively discharged. This volumetric efficiency is particularly high for fluids with higher viscosity, because the higher viscosity further reduces backflow.

5. Strong applicability:

The rotary lobe pump can be used in a variety of industries and applications such as food and beverage, chemicals, cosmetics and pharmaceuticals, further improving its efficiency in different environments. It is particularly suitable for conveying high-viscosity fluids (such as oils, syrups, chocolate, resins, etc.), liquids containing a small amount of particles and sensitive media.

6. Energy saving:

The positive displacement and high-efficiency design of the rotor pump make it consume less energy than other types of pumps, especially when handling viscous fluids.

7. Low shear

The low shear force design of the rotor pump (such as the three-blade rotor pump) is suitable for conveying fluids that are easily emulsified or shear-sensitive (such as yogurt, cosmetic raw materials).

8. High efficiency:

The speed is low (100-500r/min), and the volumetric efficiency is high when conveying liquids with high viscosity, and the overall efficiency will also be improved.

1. Food and beverage industry:

The rotary lobe pump is used to produce a variety of food and beverage products, including dairy products, chocolate, syrup, cheese, yogurt, ketchup, etc. due to its sanitary design and gentle pumping action. For example, filling production lines, CIP/SIP cleaning systems, etc.

2. Chemical and pharmaceutical:

The lobe pump can handle sensitive and corrosive fluids, making it very suitable for chemical and pharmaceutical applications.

3. Cosmetics:

The rotary lobe pump has excellent performance in conveying low-shear, sensitive, and sterile media, such as lotions and creams.

Sanitary Lobe pumps are highly efficient in liquid delivery due to their ability to handle a wide range of viscosities, gentle delivery action, and versatility in various industries. Selecting the right lobe pump for your application and considering specific operating conditions such as viscosity, flow, temperature, and pressure requirements is critical to achieving optimal efficiency and performance. This is especially true in applications that require handling of viscous or granular fluids, while also saving energy and achieving smooth operation.