2025-08-08

2025-08-08

Optimizing the sealing performance of mixproof butterfly valve requires the combination of proper selection, installation, and a rigorous maintenance schedule. Unlike standard sanitary butterfly valves, mixproof butterfly valves utilize a double-seat design and incorporate a leak chamber, making their sealing performance crucial for preventing cross-contamination.

In addition to the standard sanitary butterfly valve's ability to connect or disconnect pipelines, mixproof butterfly valves also feature leak detection and a cleanable mixproof isolation chamber. DONJOY’s mixproof butterfly valves are available in two styles: Type A and Type B. Type A features a single butterfly valve and a single seal, while Type B features two discs and two seals.

1.1 Valve Installation Precautions

Inspect the valve passage and sealing surfaces. They must be clean and free of foreign matter, and any scratches, nicks, or other defects are prohibited.

Before installation, check that the valve opens and closes freely and fully open and close the butterfly valve several times to ensure proper operation.

The upstream and downstream pipelines should be coaxial, and the sealing surfaces of the two flanges should be parallel. The piping must be able to support the weight of the butterfly valve; otherwise, supports are required.

1.2 Welding Precautions

Before welding the valve, the valve body must be removed.

Do not reinstall the valve body immediately after welding.

After installing the valve, check that the valve opens and closes properly.

1.3 Actuator Air Supply Connection (Optional)

This option only applies to butterfly valves equipped with pneumatic actuators.

• Stainless steel pneumatic actuators: Air supply connection thread BSP 1/8"

Air pipe diameter 6mm

• Air supply pressure range: 5-7 bar

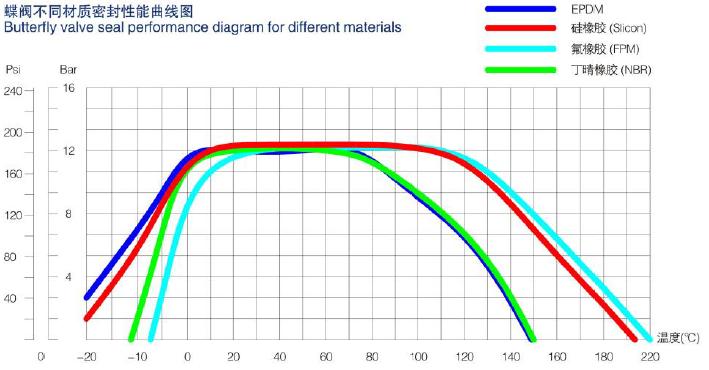

Performance curve of mixproof butterfly valve sealing

Choosing the appropriate sealing material:

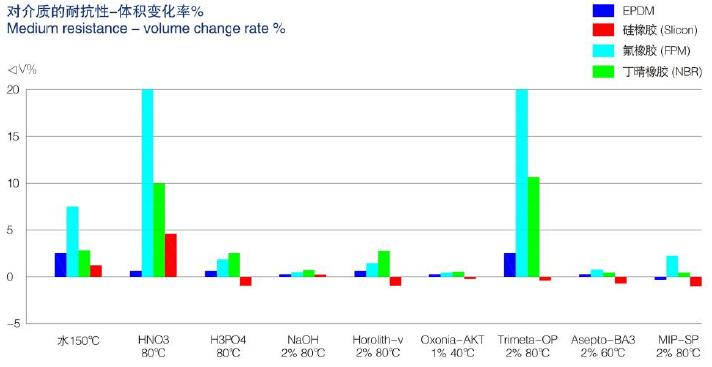

Select a sealing material that is compatible with the process media and can withstand the operating conditions (pressure, temperature, etc.). Sealing materials include EPDM, silicone, fluororubber, NBR, and HNBR.

For oily media, choose HNBR; for highly corrosive media, choose fluororubber; for other general media, choose EPDM. In addition, the sealing ring must comply with FDA standards.

Ensure smooth sealing surfaces:

The mating surfaces between the valve stem, packing, and valve seat should be smooth, free of scratches or defects, to minimize leak paths.

Regular Maintenance Kit: Seals are the primary wear component of any valve. Follow the manufacturer's instructions and replace seals at the recommended intervals. Apply a generous amount of grease when replacing the seals.

Regular Inspection and Cleaning: Leaks are visible, so regularly inspect the valve for any external signs of leakage and clean the isolation chamber regularly.

The valve cavity can be cleaned regularly using CIP.