2025-09-04

2025-09-04

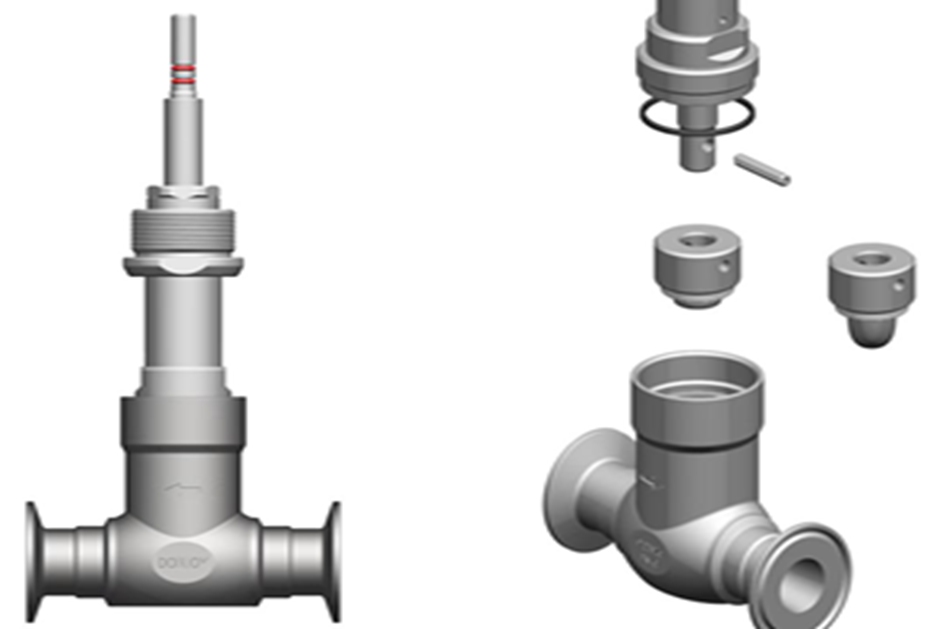

DONJOY new generation of sanitary pneumatic globe valves, powered by compressed gas, are responsible for shutting off or connecting media flow, ensuring the orderly operation of the entire industrial process. The operating principle is based on the action of a pneumatic actuator. When the external control signal changes, the pneumatic actuator converts air pressure into force, controlling the valve opening to control the flow of the fluid, thereby achieving fluid control. When the pneumatic piston receives a signal from the control air source, it pushes the valve stem downward, separating the valve disc from the valve seat, opening the valve and allowing smooth flow of the medium. Conversely, when the actuator receives a signal from the control air source to close, the pneumatic piston pulls back the valve stem, allowing the valve disc to tightly contact the valve seat, closing the valve and preventing the flow of the medium.

The new generation of hygienic pneumatic globe valves boasts a highly compact structure and a small footprint. This effectively conserves valuable space in industrial plants, facilitating the layout of other equipment. Furthermore, the low flow resistance allows for smoother flow of media in pipelines, reducing energy loss and significantly improving industrial production efficiency. This is analogous to unobstructed lanes on a highway, allowing vehicles to travel quickly and improving transportation efficiency.

During opening and closing, the new generation of hygienic pneumatic globe valves are silent, have no dead angles, and exhibit zero leakage, making them excellent performers in applications with stringent environmental and media requirements. In the food and beverage industry, production processes require strict hygienic controls. Any leakage could lead to product contamination and compromise food safety. The zero-leakage characteristics of food grade pneumatic globe valves ensure a clean production environment and guarantee product quality. In the pharmaceutical industry, lack of dead angles prevents drug residue, ensuring drug purity and efficacy.

Sanitary pneumatic stainless steel can be reversibly installed, allowing for both normally open and normally closed modes using the same actuator, providing significant user convenience. In practice, users do not need to prepare multiple actuators for different operating modes, reducing equipment procurement costs and maintenance workload.

Conventional and adjustable discs are freely interchangeable to meet different usage requirements. When production processes change and precise adjustment of media flow is required, users can easily switch functions by simply replacing the adjustable disc, without having to replace the entire valve. This saves time and costs while increasing equipment utilization.

•Size Range: 0.5"-4"/DN10-DN100

•Pressure Range: Full Vacuum to 10 bar

•Operating Temperature: -10°C to 150°C (180°C optional)

•Applicable Media: Water, oil, gas, steam, and other media

•Connection Types: Clamp, welded, threaded, flanged

•Air Source Pressure: 5-7 bar

•Air Source Port: G 1/4

•Steel Material: AISI 304/1.4301, 316L/1.4404

External Surface Finish: Matte, sandblasted

Inner Surface Finish: Bright (polished), Ra < 0.8 μm

Flow Seal: PTFE

Sanitary pneumatic control globe valves offer a wide variety of interface types, including clamps, welds, threads, and flanges. These interface types can meet the connection requirements of various industrial scenarios.

•In industries such as food and pharmaceuticals, which have high hygiene requirements, clamp interfaces are easy to install and disassemble, facilitate equipment cleaning and maintenance, and effectively prevent media residue and contamination.

•Welded interfaces are suitable for high-temperature, high-pressure piping systems with extremely high sealing requirements.

•Threaded interfaces are commonly used in small-diameter pipelines and low-pressure systems, owing to their simple installation and low cost.

•Flange interfaces, due to their high strength and strong pressure-bearing capacity, play an important role in connecting large industrial equipment and high-pressure pipelines.

•In the food industry, sanitary pneumatic stop valves accurately control the flow of raw fruit juice, water, sugar, and other ingredients, ensuring consistent beverage taste and quality.

•In the beer brewing process, hygienic pneumatic control stop valves are used to control the addition of ingredients such as wort, hops, and yeast, as well as the emission of carbon dioxide during fermentation, ensuring the flavor and quality of the beer. No dead angle, easy-to-clean design effectively prevents food residue and bacterial growth, meeting the food industry's stringent hygiene and safety standards, allowing consumers to enjoy a variety of food and beverages with confidence.

•The pharmaceutical industry has stringent hygiene requirements for production environments and equipment. Any minor contamination could affect the quality and safety of pharmaceuticals, and high quality pneumatic sanitary globe valves safeguard pharmaceutical production. The pharmaceutical production process requires the use of various chemical raw materials and solvents, which are often corrosive. Full bore sanitary pneumatic globe control valves utilize corrosion-resistant materials and high-precision surface treatment processes to effectively prevent leakage and contamination, ensuring a clean pharmaceutical production environment. During the drug filling process, high purity sanitary globe valves can precisely control the flow rate and velocity of liquids, ensuring the exact filling volume for each bottle, improving production efficiency and product quality. The zero-leakage characteristics also avoid drug waste and contamination, meeting the pharmaceutical industry's stringent requirements for environmental protection and hygiene.

As a key equipment in the industrial field, sanitary pneumatic globe valves will continue to play an important role in future industrial development with their continuously innovative technology and excellent performance, and contribute to the promotion of industrial modernization.Want to know more? Contact DONJOY!

Why sanitary stainless steel butterfly valves corrosion resistant?