2025-05-12

2025-05-12

First, check whether the pneumatic butterfly valve is complete before installation. No scratches, gaps or other defects are allowed.

Secondly, the valve is welded or clamped into the pipeline. Note that the valve body must be removed before welding to the pipeline.

Finally, the pneumatic actuator connected to the air source and check whether the valve is working properly.

1. Remove the protective cover of the interface end and other packing materials.

2. Check the butterfly valve channel and sealing surface.

They should be clean and free of foreign matter. Scratches, nicks, etc are not allowed.

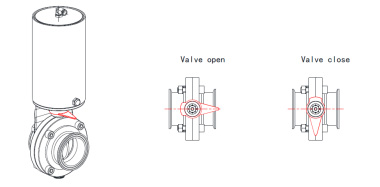

3. Check whether the valve switch is flexible before installation, and fully open and close the valve several times to ensure its normal operation.

4. Ensure there is service clearance for inspection and maintenance of the valve.

5. The front and rear pipelines should be coaxial, and the sealing surfaces of the two flanges should be parallel. The pipeline should be able to bear the weight of the valve, otherwise the pipeline must be equipped with supports.

6. Either end of the valve can be used as the inlet end.

1. Valve welding must be performed by qualified personnel.

2. The valve body must be removed before welding the valve

3. After welding, it is not allowed to install the valve body immediately.

4. After the valve is installed, check again whether the valve is opened and closed normally.

• This item only applies to Sanitary Pneumatic Butterfly Valves equipped with pneumatic actuators

• Stainless steel pneumatic actuator: Air supply connection thread G 1/8

Air pipe diameter 6mm

• Horizontal pneumatic actuator: Air connection thread G 1/4

Air pipe diameter 8mm

• Air pressure range:5-7bar

1. Safety Maintenance instructions

• Before maintenance, it must be confirmed that the pressure in the pipeline has been relieved.

• Before maintenance, take necessary protective measures to avoid damage by the medium in the pipeline or

valve.

2. Maintenance period

• Ensure that there is a stock of seals

• After the valve is put into use, it should be inspected and maintained regularly every 3 months

• The seal ring shall be replaced every 12 months or when damage is found

Note: To use a proper amount of lubricating grease when replacing sealing ring, refer to the sheet below:

|

Material of seal |

lubricating oil model |

Brand |

|

NBR |

Klubersynth UH1 64-2403 |

KLUBER |

|

EPDM/NBR/FPM |

PARALIQ GTE 703 |

KLUBER |

1 Safety precautions

• Harsh cleaning products such as caustic soda and nitric acid can cause skin burns

• Please wear rubber gloves when cleaning

• Wear goggles when cleaning

2 CIP cleaning

• This valve supports CIP online cleaning, and can also be cleaned after disassembly.

CIP Cleaning Solvents

Only mix the cleaning solution with clean (chlorine-free) water

a)Alkaline solution:

1% Caustic soda T70℃(150℉)

1kg NaOH + 100 L Water=Cleaning Solvents

2.2L 33% NaOH + 100L Water=Cleaning Solvents

b) Acid solution:

0.5% Nitric acid(HNO3) T 70℃(150℉)

0.7L 53% HNO3 + 100L Water=Cleaning Solvents

• Controlling the concentration of detergent may cause damage to seals

• To remove residual detergent, rinse with clean water after completing the cleaning process.

3. SIP sterilization

• SIP online sterilization is available on the valve.

• Before temperature is lower than 60°C, no cold liquid is allowed to enter into the equipment.

Allowed working condition of steam or superheated water in SIP process

a)Max. temperature: 140℃

b)Max. time: 30min

c)Cooling medium: sterile air or inert gas

d)Sealing material: EPDM (recommended)/FPM

Why sanitary stainless steel butterfly valves corrosion resistant?