Specification range: 0.25"-0.75"/DN6-DN15

Pressure range: full vacuum ~ 10bar

Working temperature: -10℃ to 120℃ (150℃ optional)

Applicable media: water, oil, gas and other media

Connection way : clamp, welding, trhead,flange

Material: AISI 304/1.4301 316L/1.4404

External surface finish: matte, sandblasting Internal surface finish: bright (polished), Ra<0.8um Over-current seal: EPDM/FPM/EPDM+PTFE

Standard: DIN,BPE,3A,SMS,ISO

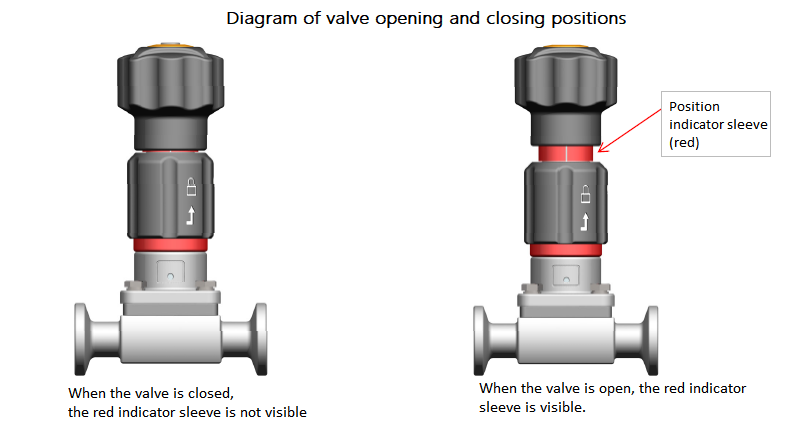

Hygienic mini manual diaphragm valve with safe lock is a valve that controls the fluid on/off and flow rate through manual operation and has a locking function. It has the characteristics of compact structure and good sealing, and is widely used in many fields such as pharmaceutical, food and beverage, industrial production etc.

Product Features:

Applications:

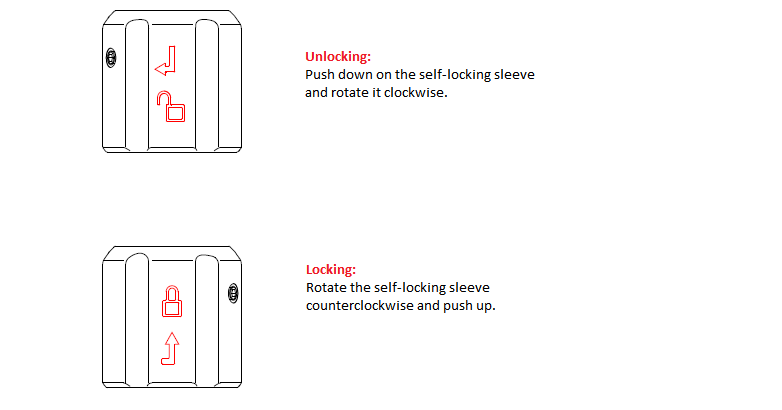

How to locking and unlocking the valve?

Unlocking: When the valve is locked, push down the self-locking sleeve and rotate it clockwise.

Locking: When the valve is unlocked, rotate the self-locking sleeve counterclockwise and push up.

The mini manual diaphragm valve with lock is a valve that controls the fluid on/off and flow rate through manual operation and has a locking function. It has the characteristics of compact structure and good sealing, and is widely used in many fields.

The locking mechanism design of the mini manual diaphragm valve with a lock offers significant practical value. In addition to the aforementioned uses, it also plays a crucial role in ensuring production safety and improving product quality.

Ensuring Production Safety: When the valve is closed, the locking mechanism acts as a solid "physical lock" on the valve stem. Regardless of pressure shocks from the fluid in the pipeline or vibrations from on-site equipment operation, the disc's position cannot be disturbed. This completely eliminates the risk of internal leakage caused by accidental valve movement, providing a solid defense for process safety and environmental protection.

Improving Product Quality: In industries with extremely high product quality requirements, such as pharmaceuticals and food, the manual diaphragm valve with a lock can adjust the disc to the desired opening position based on production process requirements and then secure it with a locking mechanism, ensuring that the valve opening remains unchanged during production. In the pharmaceutical industry, for example, this feature has increased the yield rate of pharmaceutical production from 85% to over 95%, ensuring stable and consistent product quality.

| File | Language | Size |

|---|---|---|

Diaphragm valve catalogue Diaphragm valve catalogue |

English | 18.63MB |

Sanitary valves catalogue Sanitary valves catalogue |

English | 30.2MB |