Size: 1"-4"/DN20-DN100

Pressure Range: Full Vacuum ~ 10bar

Operating Temperature: -10℃ to 120℃ (150℃ optional)

Applicable Media: Water, Oil, Gas, and other media

Connection Types: Clamp, Welded, Threaded, Flange

Valve Body Types: Straight-through/T-type/U-type

Material: AISI 304/1.4301 316L/1.4404

Diaphragm material: EPDM/FPM/EPDM+PTFE

External Surface Finish: Matte, Sandblasted

Internal Surface Finish: Bright (Polished), Ra < 0.8um

Standard: DIN,BPE,3A,SMS,ISO

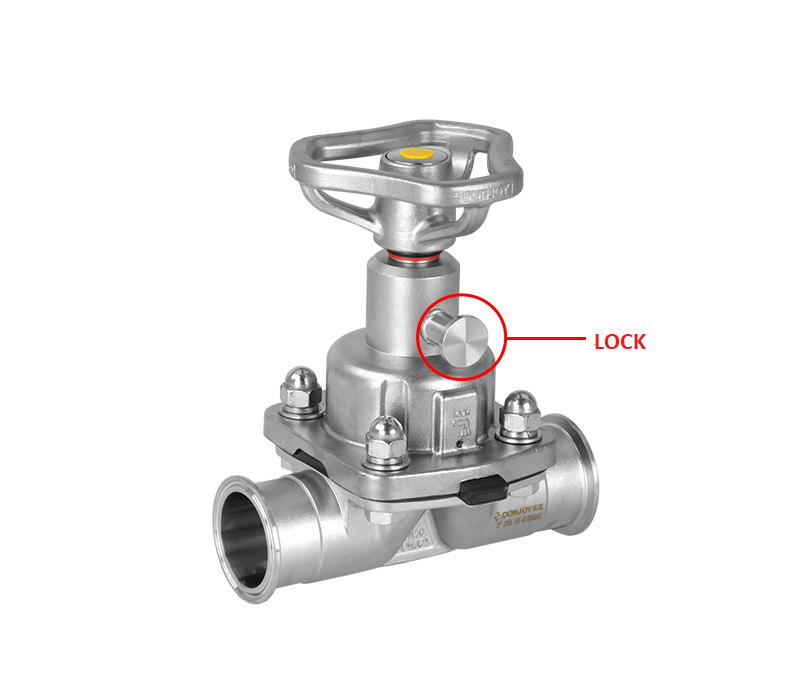

DONJOY lockable sanitary manual diaphragm valve features a locking mechanism at the valve stem position. After turning the handwheel to move the valve stem and valve disc to the desired position, simply operate the locking mechanism to fix the valve disc in place, ensuring it won't move arbitrarily. This ability to precisely control and lock the valve disc position makes it stand out among many ordinary manual diaphragm valves, making it a more flexible and precise option in the field of industrial fluid control.

Traditional hygienic manual valves are prone to displacement when faced with pressure fluctuations, system vibrations, or accidental impacts. This "hidden threat" has become a pain point for many companies and users, especially in critical processes in industries such as chemical, pharmaceutical, and water treatment. The leakage risk or adjustment deviation caused by accidental valve loosening can range from affecting production quality to causing safety accidents. Faced with this troublesome problem, engineers and customer service overcame various difficulties and ultimately developed a solution: adding a small lock to the diaphragm valve. This ensures production safety, improves product quality, achieves precise control, and reduces operating costs.

Product Features:

Applications:

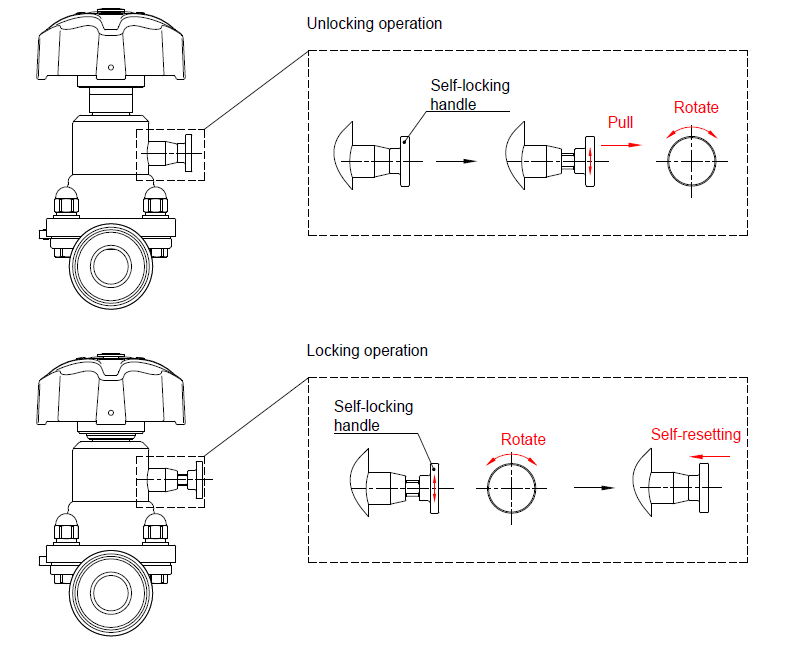

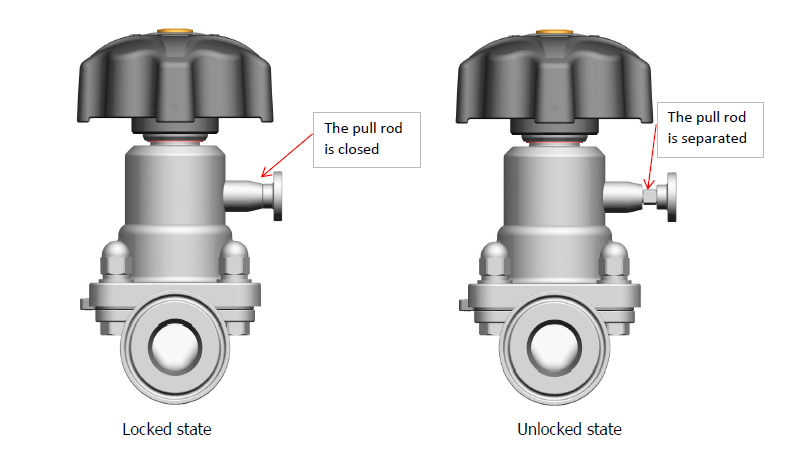

How to locking and unlocking the valve?

Unlocking operation: Pull out the self-locking handle and rotate it approximately 90 degrees.

Locking operation: Rotate the self-locking handle to make it automatically reset.

DONJOY lockable sanitary manual diaphragm valve features a locking mechanism at the valve stem position. After turning the handwheel to move the valve stem and valve disc to the desired position, simply operate the locking mechanism to fix the valve disc in place, ensuring it won't move arbitrarily. This ability to precisely control and lock the valve disc position makes it stand out among many ordinary manual diaphragm valves, making it a more flexible and precise option in the field of industrial fluid control.

Traditional hygienic manual valves are prone to displacement when faced with pressure fluctuations, system vibrations, or accidental impacts. This "hidden threat" has become a pain point for many companies and users, especially in critical processes in industries such as chemical, pharmaceutical, and water treatment. The leakage risk or adjustment deviation caused by accidental valve loosening can range from affecting production quality to causing safety accidents. Faced with this troublesome problem, engineers and customer service overcame various difficulties and ultimately developed a solution: adding a small lock to the diaphragm valve. This ensures production safety, improves product quality, achieves precise control, and reduces operating costs.

| File | Language | Size |

|---|---|---|

Diaphragm valve catalogue Diaphragm valve catalogue |

English | 18.63MB |

Sanitary valves catalogue Sanitary valves catalogue |

English | 30.2MB |